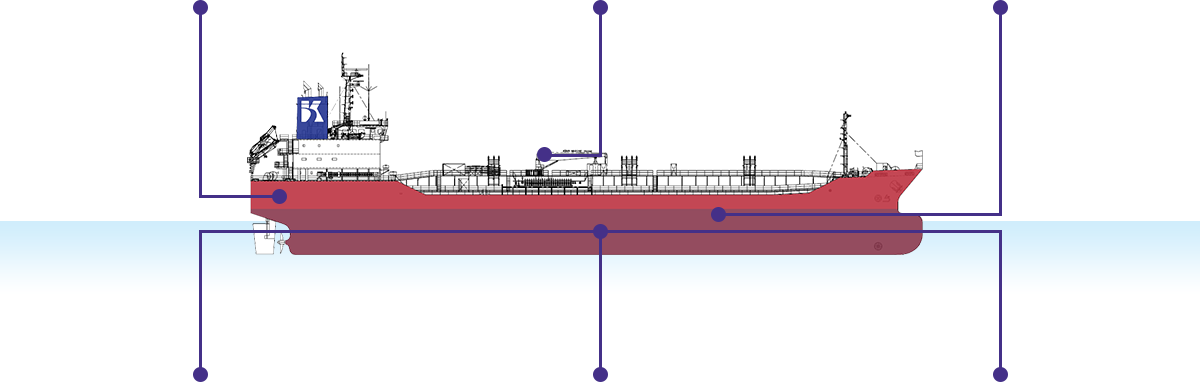

Our Chemical Tankers

N2 Generator

The cargo we handle may become volatile or their properties may change when oxidized.

To avoid incidents, our vessels are equipped with N2 Generators which maintain a blanket of nitrogen over the cargo in each tank in order to reduce or effectively eliminate contact with oxygen.Cargo Manifold / Cargo Line

To handle various liquid cargoes, our vessels are equipped with individual cargo line manifolds that connect each line to hoses from the shore.

Each tank has a fully-segregated cargo line and pump to prevent cargo contamination.Double-Hull

In case of emergency, such as grounding or collision, double-sided and double-bottomed hulls reduce the risk of oil spills and damage to cargo.

Stainless Steel Cargo Tanks

Stainless tanks are best-suited for shipping various chemical products.

We equip our vessels with stainless tanks to best ensure the integrity of the products that we carry and prevent contamination from previous cargoes. Many products require stainless steel tanks.Cargo Heating Coils

Some cargoes are required to be kept at a certain temperature range. Our vessels are equipped with cargo heating coils in each tank to maintain the cargo temperature when required.

Cargo Pumps

Cargo pumps discharge cargoes from tanks.

We equip our cargo tanks with individual deepwell pumps.

Steps for Dry-Docking

Docking

Inspections and surveys at dry-docking are required to resolve issues that cannot be solved through normal maintenance/repair at sea and also for checking the ship's bottom which is usually under water.

Maintenance / Survey

We carry out an optional survey on all of our vessels every 2-2.5 years as well as the mandatory Special Survey every 5 years.

The main engine is overhauled, the propeller is polished, etc. Everywhere is checked thoroughly.

Sea Trial

After maintenance, a sea trial is necessary.

The vessel's performance is checked to see if it meets expectations.

Special care is taken for the main engine performance as it is a big problem if the engine stops for any length of time.

Company Profile

Company Profile Statement

Statement History

History Access

Access Work for Safety

Work for Safety Work for the Environment

Work for the Environment Intra South East Asia Trade

Intra South East Asia Trade Our Chemical Tankers

Our Chemical Tankers About Our Cargoes

About Our Cargoes Fleet List

Fleet List